Static Management

Leading Supplier & Manufacturer of Static Control Products

Static Control Solutions

Static Clean provides a comprehensive range of static control and static generation solutions designed to eliminate the risks and inefficiencies caused by uncontrolled static in manufacturing environments. Our products address common challenges such as explosions, operator shock, material jams, dust attraction, product defects, and electrostatic discharge (ESD) events across a wide range of applications—including converting, molding, electronics manufacturing, cleanrooms, and other industrial processes. From standard static control devices to fully engineered solutions, Static Clean helps manufacturers improve safety, product quality, and operational uptime.

Neutralize unwanted static charge that causes defects, contamination, and handling issues. Solutions include ionizing bars, blowers, guns, nozzles, air knives, passive devices, and engineered systems designed to reduce dust attraction and protect sensitive processes and equipment. These solutions are used across a wide range of manufacturing environments to improve quality, safety, and operational efficiency.

Static generators provide a safe, clean, and efficient way to temporarily bond materials using controlled electrostatic charge. Common applications include in-mold labeling, edge pinning, chill-roll tacking, laminating, card deck static, film sealing, automated roll changeover, and insertion. Product offerings include static bond power supplies, charging bars, and spot chargers for OEM and end-user applications.

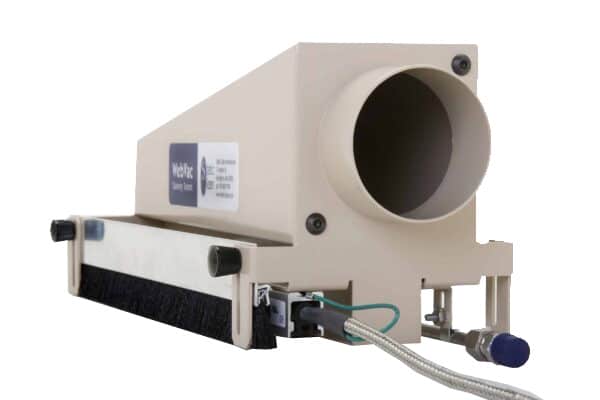

During converting operations—such as slitting, sheeting, printing, and laminating—static forces attract particles that lead to defects, downtime, and reduced product quality. Static Clean’s particulate removal solutions are designed to control static and remove contaminants from film, paper, foil, and other substrates, helping manufacturers maintain cleaner processes and achieve consistent, high-quality output.