660 Static Discharger Brush for Industrial Applications

Product Overview

Features

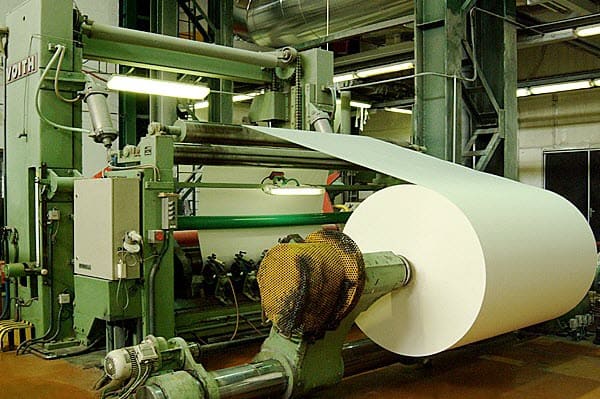

The 660 Static Discharger is a compact and cost-effective solution for static elimination, designed to reduce high static charges to low levels without requiring electrical power. Its versatile design allows for installation on a variety of machinery, including paper handling, packaging, labelling, coding, and printing equipment. The 660’s fine conductive stainless steel fiber tips create ionized air, which allows static charges to flow to earth, effectively neutralizing static electricity.

The soft fibers have the texture of sewing cotton and won’t scratch materials even when in contact. This design makes the 660 ideal for delicate applications. The fibers also have an EVA size, a protective coating that gives them resilience, flexibility, and long life. The 660 Static Discharger is available in 1000 mm lengths, which can be cut to size, allowing flexibility in installation. The discharger can also be used in multiple shorter sections to form circles or other non-linear shapes, making it adaptable to various applications.

Performance

The 660 Static Discharger performs effectively by concentrating the electric field through its fine stainless steel fiber tips. The ionized air created by these tips allows static charges to flow to earth, reducing the risk of static-related issues. This method of static elimination is simple yet effective, providing consistent results across a range of applications. The 660 discharger is available in 1000 mm lengths and can be cut to suit specific requirements, allowing it to be used in different configurations.

The discharger must be connected to earth to ensure proper static elimination. For applications wider than 1000 mm, multiple 660 Static Dischargers can be joined together on a metal bracket. This flexibility and adaptability make it suitable for a wide range of industrial uses, including web and sheet processing.

Value for Money

The 660 Static Discharger offers excellent value for money due to its low cost and effective static elimination capabilities. Its simple installation and lack of electrical requirements contribute to reduced costs and ease of use. The compact design and ability to cut to size add to its versatility, allowing it to be used in various applications without significant modifications.

The discharger’s durability, thanks to the EVA-coated stainless steel fibers, ensures a long life with minimal maintenance. Its flexibility in installation and adaptability to different shapes and configurations make it a valuable addition to any industrial process needing static control. Overall, the 660 Static Discharger provides a cost-effective, efficient, and easy-to-use solution for static elimination in a wide range of industries and applications.

Related Products

Related products

-

Static Control Solutions

4103 High Speed Static Bar – Slim Profile, Anti-Static Bar for Industrial Applications

-

Static Control Solutions

AK4100 Air Knife

-

Static Control Solutions

Defender 2-Fan Ionizer for Static and Contamination Control

-

Static Control Solutions

801 Anti-Static Copper Tinsel for Industrial Applications

-

Static Control Solutions

X-33 Intelligent Static Bar