How do you know if you have a static problem?

Detecting static electricity promptly in industrial operations is paramount to safeguard personnel and machinery. Undetected static buildup can act as an ignition source for flammable materials, jeopardize sensitive electronic components, and disrupt material handling processes. Early detection prevents costly equipment damage and production downtimes and averts potential safety hazards, ensuring that operations run smoothly, products maintain their quality, and the overall environment remains safe for workers. As such, timely recognition and management of static electricity is a proactive strategy that can save significant resources and protect a company’s reputation.

Here are some ways to recognize a static problem in industrial settings:

- Dust and Particle Attraction: Static charges can attract and hold onto dust, dirt, and other particles. If surfaces or products seem excessively dusty or if particles adhere to objects without an apparent reason, static might be the culprit.

- Product Damage or Quality Issues: In processes involving plastics, textiles, or other insulating materials, static can lead to problems like material sticking together or being rejected by machinery.

- Visual and Auditory Signs: Static electricity can sometimes cause visible sparks when a charged object or person comes into contact with a conductor. You might also hear cracking or snapping sounds.

- Shocks and Electrostatic Discharge (ESD): If personnel are frequently experiencing minor shocks when touching metal surfaces or equipment, this is a clear indication of a static problem.

- Equipment Malfunctions: Electronic components are particularly sensitive to static electricity. Unexpected equipment failures, malfunctions, or errors might be a result of static discharge.

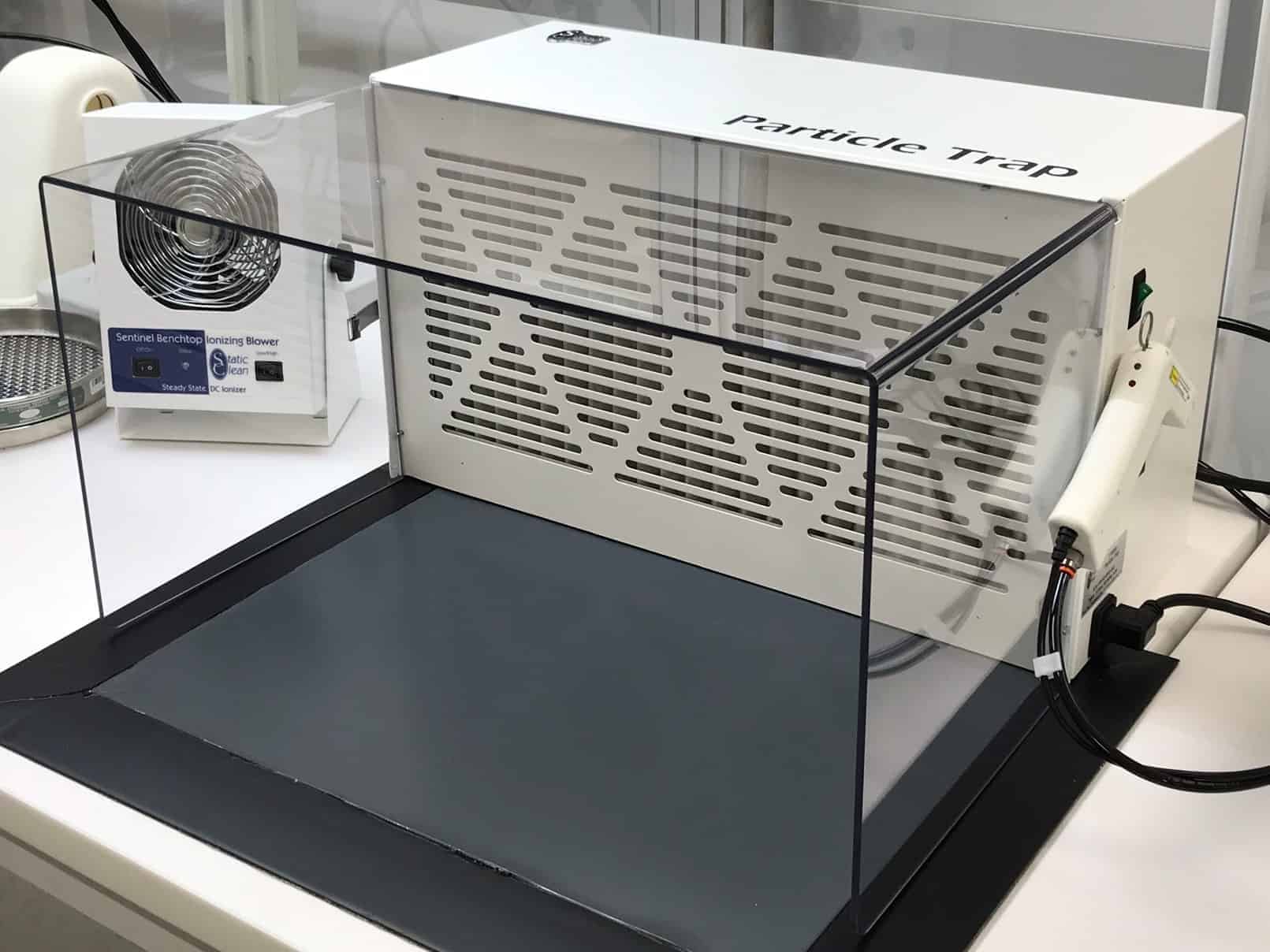

- Tools and Measurement Devices: There are tools designed to measure static electricity, like the Statiron DZ4 Digital Field Meter from Static Clean International. This is a specialized tool from Static Clean that can detect hot spots of static in various industrial settings. It not only helps in measuring static electricity but also aids in contamination control. More information and product details can be found here.

- Interference with Electronic Devices: Static discharges can cause glitches, reboots, or even data loss in sensitive electronic devices.

- Issues in Fluid Processes: In operations involving the flow of liquids or powders through pipes or chutes, static electricity can lead to issues like clogging or uneven flow.

- Safety Incidents: In environments where flammable gases or dusts are present, static electricity can cause ignitions leading to explosions or fires.

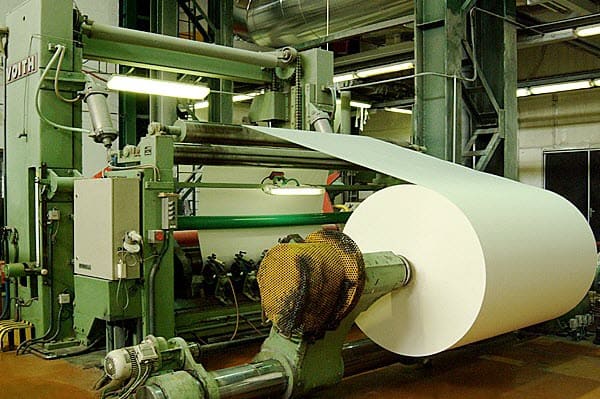

- Issues in Printing or Coating Processes: Static can cause issues with the quality of prints or coatings, leading to defects or rejects.

Static electricity in industrial operations might seem benign, but it can be the harbinger of significant dangers. One of the most critical hazards is the potential for static electricity to serve as an ignition source for flammable gases, vapors, and dusts. When charged objects or personnel discharge to grounded entities, the resultant spark, albeit seemingly insignificant, can ignite flammable substances. Industries like petrochemicals, pharmaceuticals, and grain handling are particularly vulnerable. Fires or explosions risk lives and can lead to substantial damage to infrastructure, resulting in costly repairs and lengthy downtimes. These downtimes can lead to substantial production losses, particularly in operations with high-throughput processes.

Another area of concern is the impact of electrostatic discharge (ESD) on sensitive electronic components. Microelectronics, pivotal in many modern industrial processes, are exceptionally vulnerable to ESD. A sudden static discharge can compromise or completely destroy these components. The consequences aren’t merely about replacing the damaged parts. The cascading effects, like halted operations, wastage of resources, and potential compromise of products in the production line, can lead to significant financial strain. Beyond material costs, there’s the looming challenge of recalibrating processes and ensuring quality control, which in themselves are time-consuming and expensive.

Static electricity doesn’t limit its mischief to machinery. In material handling, static can cause materials such as plastics, textiles, or papers to adhere unexpectedly, resulting in clogs or jams. These disruptions can cause machinery to malfunction or stop, demanding immediate attention. The process of addressing these jams can also expose workers to potential injuries, leading to medical expenses and compensation claims. Furthermore, the fallout from static interference in industries producing consumer goods may necessitate costly product recalls, further straining financial resources and potentially tarnishing brand reputation.

Lastly, the ripple effects of static-related incidents extend to the administrative and regulatory domains. Given the perceived risk, the legal landscape can present challenges. Lawsuits stemming from static-related accidents can be protracted and expensive, not to mention the potential reputational damage they can inflict. These multifaceted challenges underscore the importance of investing in comprehensive static control measures, which, while having their associated costs, are often a fraction of the potential financial fallout from static-induced incidents.

The benefits of controlling your static include mitigating jams, clogs, mis-feeds, poor stacking, reduced transport speeds, shocks to operators, fires, explosions & a variety of contamination-related problems. Static Eliminators are designed to help you control these troublesome and costly problems by neutralizing the static electricity that cause them. The investment in quality static control equipment will help reduce costly rejects, teardown and rework while giving you an impactful return on your investment.

Quick tips to help prevent static problems in industrial settings:

- Grounding: Ensure that equipment and machinery are properly grounded.

- Humidity Control: Maintain a controlled level of humidity as dry conditions can exacerbate static problems.

- Anti-static Mats and Flooring: Use these in areas where static-sensitive operations take place.

- Ionizing Equipment: These devices release ions to neutralize static charges on surfaces.

- Anti-static Sprays and Coatings: These can be applied to surfaces to reduce static buildup.

- Static-dissipative Footwear and Clothing: Ensure workers wear appropriate attire to reduce static buildup and discharge.

- Regular Training: Ensure that personnel are educated about the risks and mitigation strategies related to static electricity.

If you suspect a static problem in your industrial setting, consider consulting with the experts at Static Clean International to conduct an assessment and provide recommendations. Call us today at (781) 229-7799